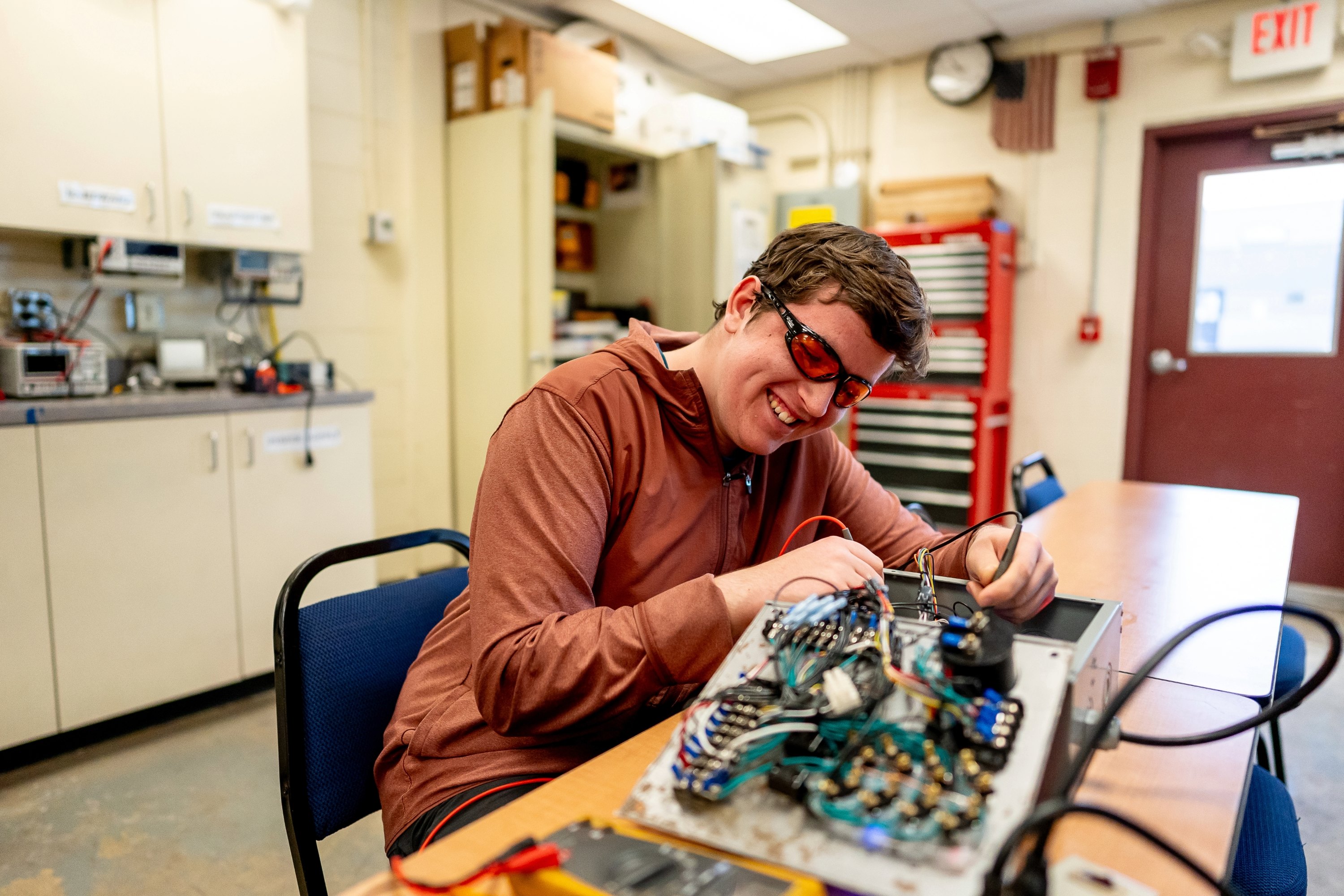

Electronics

The industrial technology - electronics program provides training for maintenance electricians and electronics technicians within industrial facilities such as wood processing plants, agricultural food storage and processing warehouses, manufacturing plants and hydroelectric power facilities. It also provides advanced-level training and skill improvement for plant electricians and other employees seeking to improve their work classification within their company on modern electronic circuits, programmable logic controllers (PLCs) and control systems.

Before entering the industrial technology - electronics program, you are strongly advised to complete one year of high school algebra or its equivalent. Prior to entry into the program, documentation of computer literacy, or BCT 105 Computer Applications, or instructor permission is required. A current first aid card with CPR is required upon graduation. Coursework in computers and basic electricity/electronics is also beneficial prior to entering the program. If you are planning additional education beyond the WVC associate of applied science degree (formerly the associate of technical science degree), work closely with your program adviser as some electronics course work may be transferable, and you may want to consider taking English 101 and Math 105 as part of your associate of applied science degree.

To be eligible for the degree, students must earn at least a cumulative 2.0 grade point average. Core program courses may have prerequisite requirements. English and mathematics courses require qualifying assessment scores or acceptable preparatory coursework in those subjects. See the course descriptions for details. If you complete the industrial technology - electronics associate of applied science degree, you can earn electrical hours toward the Washington State Labor and Industry (07) Nonresidential Maintenance Specialty Electrical License.

- For more information about careers related to this field, go to My Next Move.

- Career Pathways Roadmap

Students who complete the associate of applied science in industrial technology - electronics will be able to:

- Correctly and safely use a variety of electrical testing equipment.

- Comprehend printed installation and service literature for complex electrical equipment.

- Effectively use standardized automation software such as Rockwell Software or Siemens.

- Communicate with other professions and the general public using terminology appropriate for the electrical service industry.

- Establish or critique an existing electrical maintenance program.

- Recognize different computer network strategies used with electronic control systems.

- Accrue hours toward a Washington state electrical license.

- Acquire training and education to seek employment or advance in current employment.

- Develop a foundation to continue their studies.